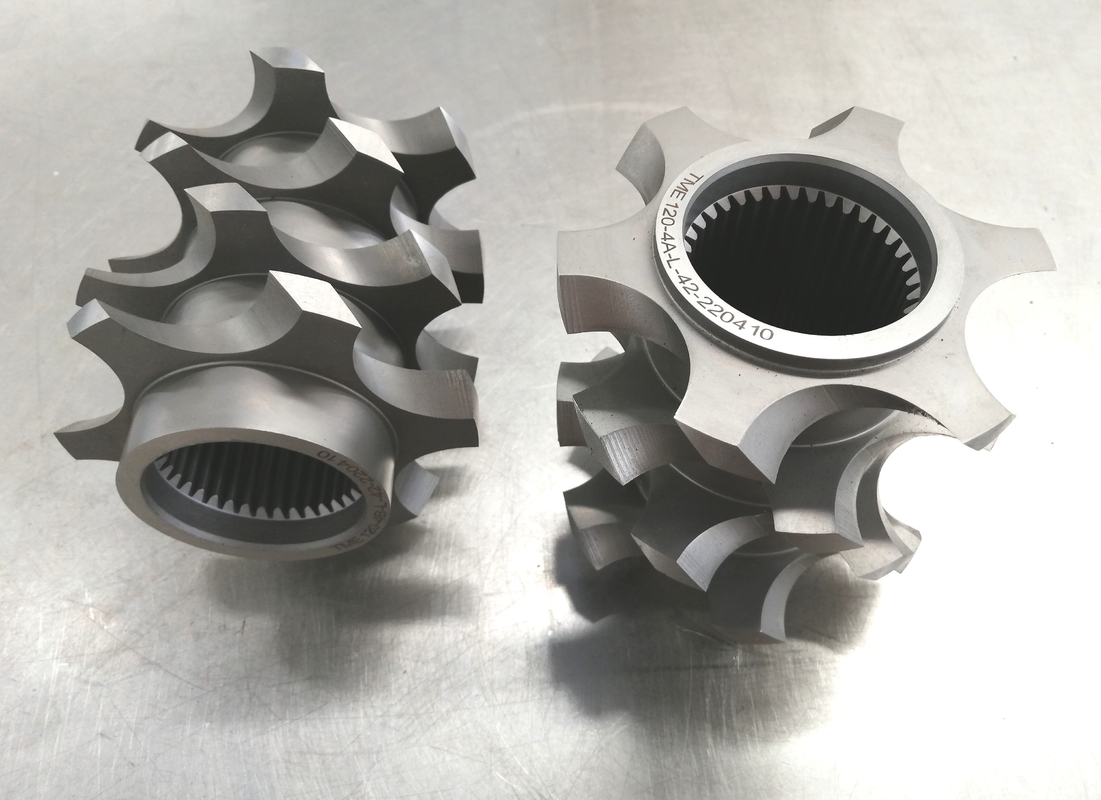

Model 110 Corrosion Resistance Extrusion Machine Screw Elements Segments

1.Brief introduction

Joiner has more than 140 advanced equipments such as CNC thread grinder, CNC thread milling, CNC kneading block grinder, CNC forming milling, 4-axis machining center, automatic deep hole grinder, CNC lathe, CNC surface grinder, CNC external grinding, CNC band saw, laser marking machine, vacuum quenching furnace and vacuum tempering furnace. We have passed ISO 9001.2015. And we conduct comprehensive quality planning and management strictly in accordance with the ISO standard and management system.

2. Process

3. Quality Control

1). Materials control: All the materials are purchased from the domestic brands or European twin-screw specialty materials suppliers, which tested by elemental analysis and metallurgical inspections to ensure the quality.

2). The internal spines is checked by the spline plug to ensure interchangeability of the elements

3). All components are machined by CNC machines to ensure the shapes and tolerances of the elements

4). Adopt the European high-speed steel powder processing technology, and do the treatment according to the strict heat treatment 4.process to ensure the wear and corrosion performance same as the foreign brands.

5). Professional technical team can not only provide timely and accurate mapping sample design but also the combination of elements of technical services.

6). There are various prepared technical information and the fixtures for the various brands extruders to ensure the timely lead time. The common components have a lot of stock, even the new one, it can be delivered within 45days.

7). The modern management system can ensure the products 100% qualified and tracked

4. Heat treatment

As we all know, heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves.

5. Product accuracy

There are some differences between Joiner Machinery and Nanjing's production technology. Their finishing process is carried out before heat treatment, and the deformation after heat treatment is not controlled, so their accuracy is not easy to control. But our finishing process is carried out after heat treatment, which can eliminate the deformation of parts in heat treatment, so the precision is higher, and thus can achieve zero seam connection.

6. Packing:

Packing Details: According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

a. Rust-proof oil processing,

b. Oiled paper packages,

c. Bubble wrap package,

d. Special foam packaging,

e. Packing,

f. Sealing.

7. Screw elements we produce:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!