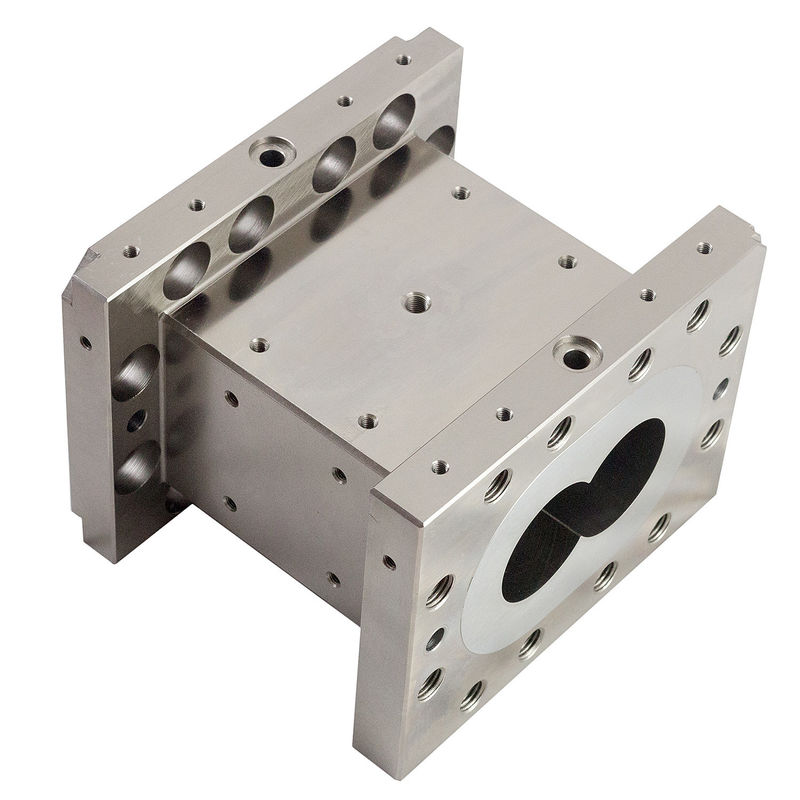

With New Design Waterway Extrusion Screw And Barrels,Screw Barrel Manufacturer

| Standard Barrel Parameter Table (selection table) |

| Model |

Size(mm)

W.H.L |

Hole Diameter(mm) |

r Distance(mm) |

| JN-20 |

115.105.132 |

Φ23 |

18.4 |

| JN-30 |

135.115.120 |

Φ30.6 |

26 |

| JN-35 |

140.120.140 |

Φ36 |

30 |

| JN-36 |

160.140.150 |

Φ36 |

30 |

| JN-40 |

175.145.160 |

Φ41.6 |

34.5 |

| JN-50 |

190.150.190 |

Φ51 |

42 |

| JN-52 |

200.155.210 |

Φ52 |

43 |

| JN-53 |

210.160.220 |

Φ53.3 |

48 |

| JN-58 |

220.175.240 |

Φ58 |

48 |

| JN-60 |

210.170.240 |

Φ60 |

52 |

| JN-65 |

210.170.240 |

Φ63 |

52 |

| JN-75 |

260.200.290 |

Φ71.8 |

60 |

| JN-85 |

280.215.320 |

Φ81.9 |

67.8 |

| JN-92 |

310.240.360 |

Φ92 |

78 |

| JN-95 |

310.240.360 |

Φ94 |

78 |

| JN-110 |

330.240.420 |

Φ109 |

91.5 |

| JN-125 |

390.290.500 |

Φ125 |

98 |

| JN-135 |

370.300.410 |

Φ134 |

110 |

Screw type:Double Screw

Application:Plastic industry Wood plastic inflated Food powder coating

For what machine:Plastic Wood Food Twin Extruder machine

Co-rotating twin screw barrels for

APV KOBE OMC

Buhler KraussMaffei Theysohn

Buss Berstorff Toshiba

Clextral Labtech USEON

Coperion Lantai others

JSW Leistritz

Keya Maris

Range of Work

Diameter of 15.6mm-350mm

Types of Barrels

Standard for classification: Design geometry Standard for classification: With inner or not

Feeding barrel Solid barrel

Closed barrel Barrels with inners

Vent barrel

Combi barrel

Extended degassing barrel

Combi barrel with backward venting

The Barrels is used as an important part for extruder accessory. It is widely used in various extruder industries. Such as XPS extruder, PS granulator, PE pipe extrusion machine. Because of the difference of raw materials, the requirements for the Barrels are different. For example, when some glass fiber materials are extruded, the wear is larger and the gap between the screw and the Barrels is strictly required. the balance of wear resistance and cost is need to be taken full consideration.

Packaging Delivery

Packaging Details: Wooden case, Sea-worthy or export standard.

Port: SHENZHEN

Lead time: 40-50 days after order confirmation.

If you are interested in our barrels,pls call me feel free.(Wechat/Whatsapp/Tel:0086 18208137954)

FRQ

1. Q: Are you a factory or trading company?

A: A factory

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Chengdu, Sichuan Province, China,

1) You can fly to Chengdu Airport directly. We will pick you up when you arrive in the airport;

All our clients, from domestic or abroad, are warmly welcome to visit us!

3.Q: What makes you different with others?

A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86 028 87226313, we will answer your questions immediately.

2) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working days.

As a manufacturer, we can ensure the delivery time according to the formal contract.

4.Q: How about the delivery time?

A: This depends on the product. Typically standard products are delivered within 30 days.

- Q: What is the term of payment?

A: 1) T/T payment; 2) LC;

6.Q: May I know the status of my order?

A: Yes .We will send you information and photos at different production stage of your order. You will get the latest information in time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!