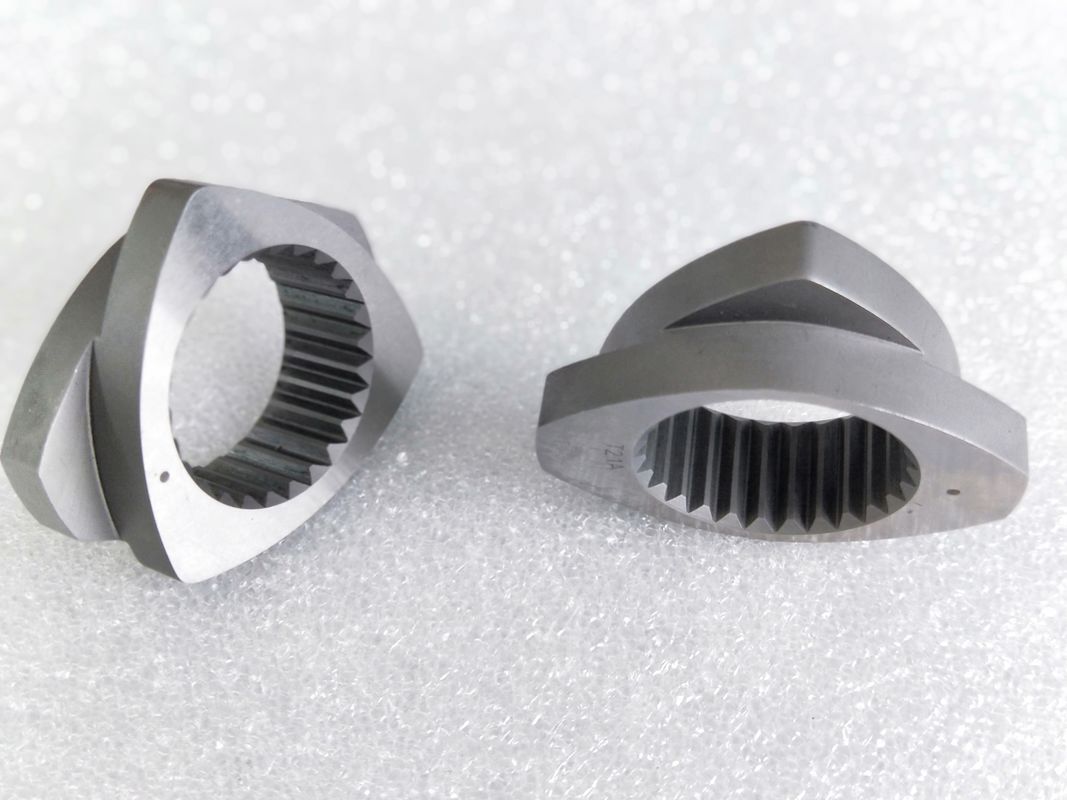

Triple Flighted To Double Flighted Transition Screw Elements / Kneading Block Of 2 Layers For Connecting

1. Screw Element Details

| Screw Design |

Double-Screw |

|

| Hardness |

58-60HRC |

| Brand Name |

Jioner |

| Surface Treatment |

Sand blast |

| Materials |

6542/1.2379/WR2/WR5/WR14 etc. |

| Place of Origin |

Sichuan, China |

| Warranty |

6 months |

| Screw Range |

Φ 15.6 - Φ 400mm |

|

Spline

|

Involute inner spline

|

2. Screw Elements Materials for Choice:

We offer a broader choice of materials:

For wear application:

* Tool Steel: HW03;

* PM-HIP material: HWA,HWC02,HWC01,CPM10V,CPM9V

For corrision application:

* Nitrided Steel: HC01;

* PM-HIP material: WR4,HWC02,HWC01,CPM10V,CPM9V

For wear and corrision application:

* PM-HIP material: HWC02,HWC01,CPM10V,CPM9V

Other materials:

* Stainless Steel: HCS01,HCS03 etc.

By working closely with customers in choosing optional materials, we can minimize wear and tear and associated costs.

3. Process of making

4. Raw material guarantee

The company has been cooperating with domestic and foreign first-line brand material suppliers for a long time, and has a strict quality control and performs regular audits and inspection of the factory (elemental analysis, metallographic analysis, ultrasonic flaw detection, etc.) to ensure a 100% qualified status.

5. Heat treatment

Heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves. In China, we are the only company that does heat treatment by ourselves, and the heat treatment of screw components made by Nanjing factory is processed by outsiders, so the quality of products can not be completely guarantee.

6. Why choose us?

a. Our convered area is 20000 square meters and the construction area is 16000 square meters;

b. There are more than 160 sets of advanced processing equipments in our plants. Such as the CNC thread grinding machine, the CNC scre milling, the CNC kneading block grinding machine, the CNC milling,the 4 axis machining center, the automatic deep hole grinding machine, the CNC lathe ,thr CNC surface grinder, the CNC cylindrical grinder, the CNC sawing machine, the laser marking machine, the vacuum

quenching furnace, the vacuum tempering furnace and so on . Ultimately,We become one-stop manufacturer for all services and thereby ensure the good quality through the internal control.

c. Therer are also some advanced testing equipments, such as the metallographic analyzer, the Taylor roughness meter, the Japanese Mitutoyo height gauge, the CMM, the Rockwell hardness tester, Vickers hardness tester and some other advanced testing equipments. which ensure the products 100% controllable;

d. Company passed the SGS ISO9001.2015 successfully, and we conduct the comprehensive quality planning and management strictly in accordance with the ISO9001 quality standard and management system.

e. The adequate inventory can ensure that customers get the products in the first time.

f. The annual production capacity of screw segments is about 4000 meters, barrels with mirror inner hole 1500pcs and 2000pcs shafts with high torque.

7. Packing Details:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

- Rust-proof oil processing,

- Oiled paper packages,

- Bubble wrap package,

- Special foam packaging,

- Packing,

- Sealing

8. Testing Reports for Our customer

We will send Inspection reports for every our customer.

1).General Dimension Inspection Report

2). Material certificate for customer.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!