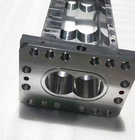

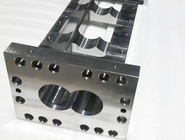

Precision CNC Machining Special Design Structure Twin Screw Extruder Barrel

1. Introduction of barrels:

Barrels are used as an important part for extruder accessory. It is widely used in various industries. Such as XPS extruder, PS granulator, PE pipe extrusion machine. Because of the difference of raw materials, the requirements for the Barrels are different. For example, when some glass fiber materials are extruded, the wear is larger and the gap between the screw and the Barrels is strictly required. the balance of wear resistance and cost is need to be taken full consideration.

We manufacture barrels for co-rotating twin screw extruders ranging from 15.6 mm to 400 mm and over. Our manufacturing specializes in barrels for twin screw extruders and is optimized for flexible order handling.

2. Standard Barrel Parameter Table:

| Standard Barrel Parameter Table (selection table) |

| Model |

Size(mm) W.H.L |

Hole Diameter (mm) |

Center Distance (mm) |

| JN-20 |

115.105.132 |

Φ23 |

18.4 |

| JN-30 |

135.115.120 |

Φ30.6 |

26 |

| JN-35 |

140.120.140 |

Φ36 |

30 |

| JN-36 |

160.140.150 |

Φ36 |

30 |

| JN-40 |

175.145.160 |

Φ41.6 |

34.5 |

| JN-50 |

190.150.190 |

Φ51 |

42 |

| JN-52 |

200.155.210 |

Φ52 |

43 |

| JN-53 |

210.160.220 |

Φ53.3 |

48 |

| JN-58 |

220.175.240 |

Φ58 |

48 |

| JN-60 |

210.170.240 |

Φ60 |

52 |

| JN-65 |

210.170.240 |

Φ63 |

52 |

| JN-75 |

260.200.290 |

Φ71.8 |

60 |

| JN-85 |

280.215.320 |

Φ81.9 |

67.8 |

| JN-92 |

310.240.360 |

Φ92 |

78 |

| JN-95 |

310.240.360 |

Φ94 |

78 |

| JN-110 |

330.240.420 |

Φ109 |

91.5 |

| JN-125 |

390.290.500 |

Φ125 |

98 |

| JN-135 |

370.300.410 |

Φ134 |

110 |

3. Materials:

Barrel Body

There are three kinds of material used for barrel’s main body, they are HB01,HB02,HC01. And HB01 is popular in domestic barrel application.

4. Types of Barrels

* Feeding barrel

* Solid barrel

* Closed barrel

* Barrels with inner liners

* Vent barrel

* Combi barrel

* Extended degassing barrel

* Combi barrel with backward venting

5. Service Network Assurance

We have a professional sales team who can quickly understand the real needs of customers, and put forward reasonable solutions for them. The company not only offers supportive services for both domestic and foreign brands, but also provides retail services to outstanding end customers in the industry. Now Joiner products are exported to more than 30 countries including countries such as Europe and America.

| 24-hour Hotline |

Pre-sales Consultation |

After-sales Services |

| No matter when and where to call we can find our service to you. |

Whether you have any question

can be solved through online

communication. Welcome your consultation. |

Having any questions about the products, please contact with us and we will help you deal with them the first time to your satisfaction.

|

6. Packing Details:

According to your order quantities and products sizes to pack:

1. Rust-proof oil processing,

2. Oiled paper packages,

3. Bubble wrap package,

4. Special foam packaging,

5. Packing,

6. Sealing.

7. Why choose us?

(1) Total solution of highly wear-resistance and corrosion-resistance problems;

(2) Expert of engineering design and consulting,

(3) Advanced manufacturing capabilities and technology,

(4) Lean production management

(5) Top quality products with high cost performance

8. FAQ:

1.Q: Are you trading company or manufacturer?

A: We are factory.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Chengdu, Sichuan Province, China, 1) You can fly to Chengdu Airport directly. We will pick you up when you arrive in the airport; All our clients from domestic or abroad are warmly welcome to visit us.

3.Q: What makes you different with others?

A: Our Excellent Service For a quick, no hassle quote just send email to us we promise to reply with a price within 24 hours - sometimes even within the hour. If you need an advice, just call our export office at +86 19150954315, we will answer your questions immediately. 2) Our quick manufacturing time For Normal orders, we will promise to produce within40 working days. As a manufacturer, we can ensure the delivery time according to the formal contract.

4. Q: What is your terms of payment ?

A: 1) T/T 2) L/C;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!