Product Description:

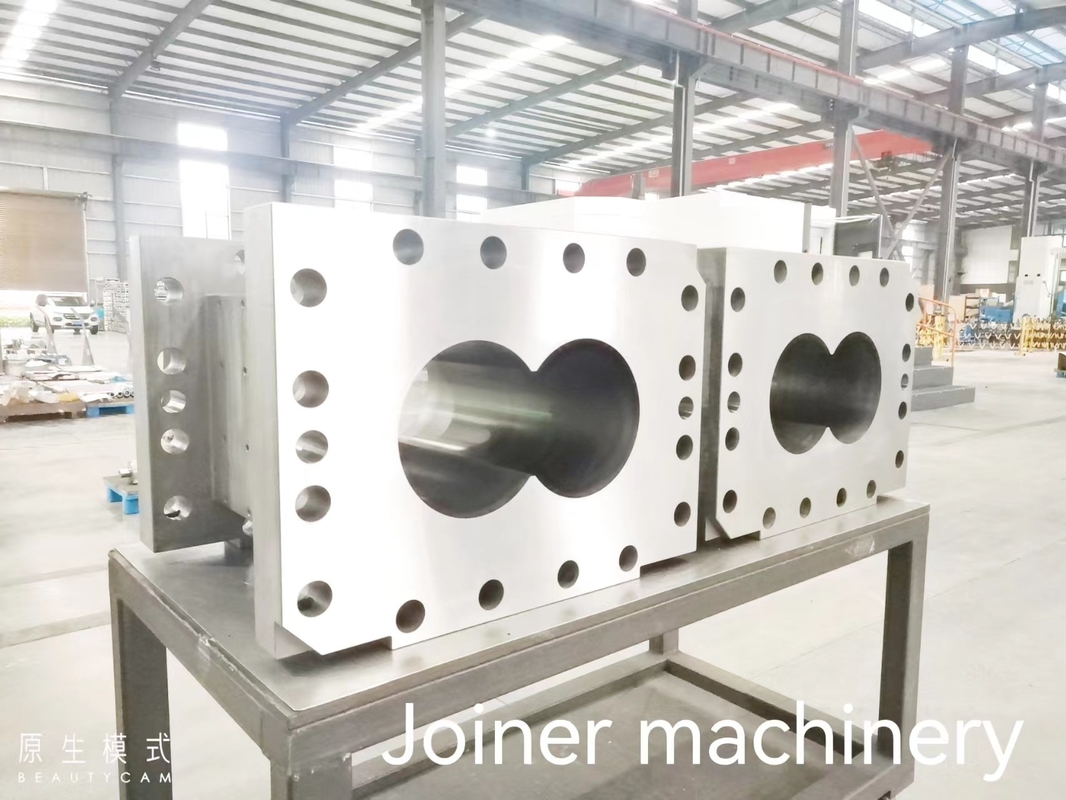

The Screw and Cylinder Unit is a system composed of a screw and a cylinder, which can be used as a transmission device. The screw and cylinder are made of alloy steel with a nitriding treatment on the surface, significantly improving the hardness and wear resistance of the unit. The cylinder has a length of 3000mm and the screw has a length of 1600mm. The barrel surface is also treated with nitriding, making it highly resistant to corrosion and wear. This Screw and Cylinder System is ideal for applications requiring high torque transmission, high efficiency operation and longer service life.

Features:

- Product Name: Screw And Barrel

- Screw Speed: 0-220rpm

- Diameter: 50-300mm

- Barrel Cooling: Water Cooling

- Surface: Nitriding Treatment

- Barrel Heating: Electric Heating

- Highlight: Screw and Cylinder Combination with High Efficiency

Technical Parameters:

| Parameter |

Details |

| Material |

Alloy Steel |

| Surface |

Nitriding Treatment |

| Hardness |

HRC50-55 |

| Accuracy |

0.03mm |

| Roughness |

Ra0.4 |

| Barrel Cooling |

Water Cooling |

| Barrel Surface |

Nitriding Treatment |

| Barrel Diameter |

300mm |

| Diameter |

50-300mm |

| Length |

1600mm |

| Product Name |

Screw and Cylinder Assembly, Screw and Barrel Combination, Screw and Barrel Assembly |

Applications:

Screw and Barrel Assembly is a combination of Screw and Cylinder that is widely used in the Twin Screw Extruder. The 150 barrel model is made of Alloy Steel, with a barrel diameter of 300mm and a barrel length of 3000mm. The surface roughness of the product is Ra0.4, and the hardness of the product is HRC50-55. This product has the advantages of good wear resistance, corrosion resistance, high temperature resistance and long service life.

The Screw and Barrel Assembly is mainly used in the plastic extrusion process, for the production of various plastic products, such as plastic film, plastic pipe, plastic sheet, plastic profile, plastic pellet and other plastic products. In addition, it is also used in rubber industry, for the production of rubber products, such as rubber hose, rubber sheet, rubber flooring and other rubber products.

The Screw and Barrel Unit is also widely used in many other areas, such as food industry, chemical industry, pharmaceutical industry, building materials industry, etc. It is an essential part of the production process for many products, and its high quality and reliable performance make it an ideal choice for many industries.

Customization:

Screw and Barrel Combination

- Brand Name: barrels for twin screw extruder

- Model Number: 150 barrel

- Place of Origin: CHINA

- BarrelLiner: Alloy Steel

- Accuracy: 0.03mm

- Diameter: 50-300mm

- Barrel Cooling: Water Cooling

- Barrel Diameter: 300mm

We offer the Screw and Barrel Unit, Screw and Cylinder Assembly, precision-engineered for superior performance in a range of applications. Our Screw and Barrel Combination is made from Alloy Steel with accuracy of 0.03mm and diameter ranging from 50 to 300mm, and are water cooled for optimal performance.

Support and Services:

Screw And Barrel Technical Support and Service

We provide a range of technical support and service for our Screw And Barrel products. Our dedicated team of experts can provide advice, guidance and support on installation, operation, maintenance and repair.

Our technical support team is available 24/7, and can be contacted by phone, email or online chat. We can provide on-site support and service where necessary, as well as remote support.

We also provide a range of spare parts and consumables for Screw And Barrel products, with a fast delivery service. We offer a range of maintenance packages, tailored to the individual requirements of our customers.

Packing and Shipping:

The Screw and Barrel will be packaged and shipped in a secure box to ensure safe delivery. The box should be large enough to fit the item securely and the additional padding should be used to help protect the item from any shocks during transit. The box should be clearly labelled with the recipient's address and delivery instructions. Any additional packaging materials, such as bubble wrap, should also be used to provide extra protection against any damage during transit.

The box should be well sealed with strong tape to prevent any tampering or water damage. The box should also be clearly marked with the sender's contact details in case any issues arise during transit. Once the box is securely sealed, it should be ready for collection and delivery.

FAQ:

Questions and Answers about Screw and Barrel

- Q: What is the brand name of the Screw and Barrel?

A: The brand name of the Screw and Barrel is barrels for twin screw extruder.

- Q: What is the model number of the Screw and Barrel?

A: The model number of the Screw and Barrel is 150 barrel.

- Q: Where is the Screw and Barrel made?

A: The Screw and Barrel is made in China.

- Q: What materials are used to make the Screw and Barrel?

A: The Screw and Barrel is made of high-quality alloy steel.

- Q: What is the size of the Screw and Barrel?

A: The size of the Screw and Barrel is 150mm.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!